Our Process

We're eager to hear your ideas! We're happy to connect and ensure a clear understanding. Our team is here to discuss details like purpose, size, materials, colors, logo options, and any other specifics you have in mind. We'll bring our expertise to help meet your expectations. No matter how you prefer to connect—whether by email, chat, or video call—we're happy to accommodate your preference and begin addressing your request.

Whether you have a reference sample, a rough sketch, or even no idea at all, don't worry—we're here to support you throughout the entire development process.

You're welcome to provide your own design file if you have one. If not, we’re happy to create it for you. To make sure we're aligned on the concept, we'll prepare a drawing for your approval.

Based on our discussions, we will recommend materials for the outer and inner shells, accessories, and logo options. With our extensive material library, we can guide you through the selection process to ensure the best choices for your design.

After we gather the initial design details, we’ll prepare a customized quote tailored to your requirements and budget, ensuring our price aligns with your total product and packaging costs.

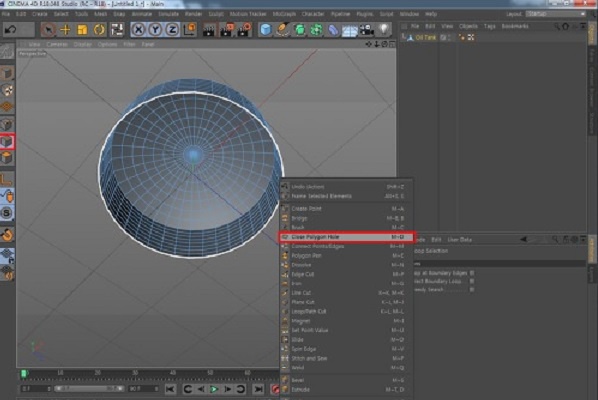

Typically, sample development takes between 5 to 10 days if existing tooling is available. If new tooling is required, please allow an additional 5 days for tooling setup. Before initiating the creation of new tooling, we will provide you with a 3D file for your approval. This ensures that every detail aligns perfectly with your requirements before proceeding with the tooling setup.

We follow a streamlined process for mass production, covering every stage from laminating and cutting to thermoforming, stitching, and trimming. Each step is carried out by specialized workers, ensuring both production efficiency and the exceptional quality of your custom EVA cases.

Once you approve the sample, standard production generally takes 15 to 45 days. This timeframe may vary depending on material availability and your delivery needs.

Golden Sample

Once you approve the golden sample as perfect for mass production, our QA team conducts thorough testing, including fit, functionality, physical durability, and more.

This ensures that production meets expectations, allowing for any necessary adjustments before moving forward with mass production.

Each EVA case undergoes a rigorous inspection process before delivery.

During this stage, we meticulously examine everything—from the exterior appearance and dimensions to even the smallest parts—to ensure there are no defects.

Our commitment to 100% inspection guarantees that every case you receive meets the same high-quality standards.

As soon as all the cases are ready, we promptly arrange for their delivery.

If you have a preferred logistics provider, we’re happy to work with them, or we can arrange shipping with our trusted forwarder.